Sofa bed manufacturer still mainly produces sofa beds by hand .That’s because assembly lines can’t produce a wide variety of products. Manual work can handle details precisely, like accurate filling and perfect edging, adapts different materials, and ensures high quality. It also meets customers’ customized needs. So, sofa bed production usually starts after the customer confirms the requirements.

Design

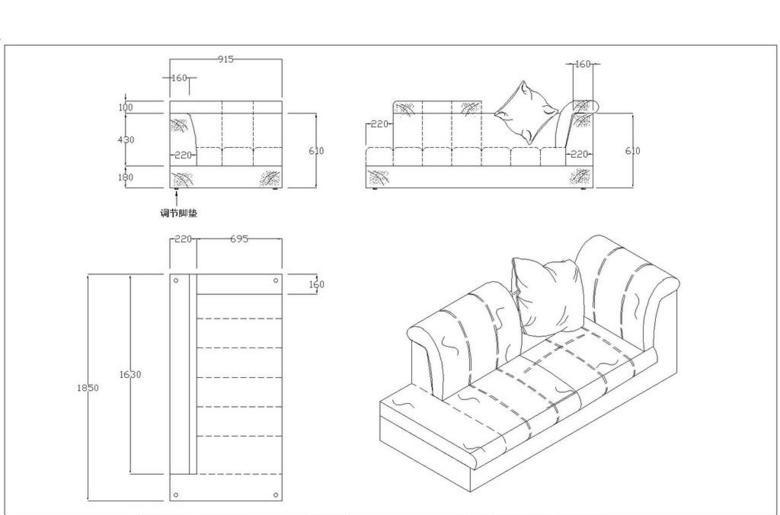

Designers lead the design. Based on market trends, consumer needs, and aesthetic principles, they consider the functionality, comfort, materials, and appearance of the sofa bed. Using CAD software, they draw and optimize detailed design drawings, including dimensions, shapes, structures, and decorative details, and then develop templates.

Material Procurement

Purchase high-quality raw materials. For example, dry the wood for the frame; choose elastic and durable sponge for filling; select fabric or leather for the surface, which should be both good-looking and comfortable and wear-resistant.

Frame Construction

Cut, splice, and reinforce the wood to make the sofa bed frame. Craftsmen measure and cut accurately to meet the design requirements. The frame’s stability is crucial for the sofa bed as it affects comfort and durability.

Spring Installation

Install support components like springs inside the frame. For example, use S springs with small tension springs or elastic bands to provide elastic support.

Sponge Placement

Cut the sponge according to the design and fix it on the frame to ensure even filling and a comfortable sitting feel. Different parts may use sponges of different densities.

Fabric or Leather Covering

Cut and sew the fabric or leather to make a cover and then put it on the sponge. Skilled craftsmen should pay attention to details to ensure a neat and beautiful appearance.

Assembly

Assemble parts such as arms, backrests, seat cushions, and guide rails. Ensure firm connections and consistency with the design. For special-function sofa beds, debugging and testing are needed.

Quality Inspection

The factory comprehensively checks the sofa bed, including its appearance, structure, comfort, and functionality. Only the qualified ones will be packaged and shipped.

Packaging

Use suitable packaging materials to protect the qualified sofa beds from damage during transportation and storage.

Sofa Bed manufacturer: Xuya starts from designers’ ideas, through careful material selection, skillful crafting and assembling, strict quality checks, to considerate packaging. It combines tradition and modernity, showing dedication to comfort. Each sofa bed, full of makers’ passion, enters homes, offering cozy personal havens and witnessing happy family times.

1 thought on “How do sofa bed manufacturer produce sofa beds-Complete Process”